Many manufacturing processes need the passivation of the Material to be certain that the surface is non-reactive and inert. With stainless steel, for example, the passivation of the surface helps in preventing corrosion or rust. For Nitinol nickel-titanium metal, the passivation of the Materials help in preventing corrosion, and also helps biocompatibility. The passivation of Nitinol will normally deplete the surface of nickel, which might cause serious allergic reactions in the human body. For substances such as Nitinol and stainless steel, whose Passivation layers may be quite thin, chemical analysis services is exactly what you need. Among the most frequently used approaches is Electron Spectroscopy Chemical Analysis.

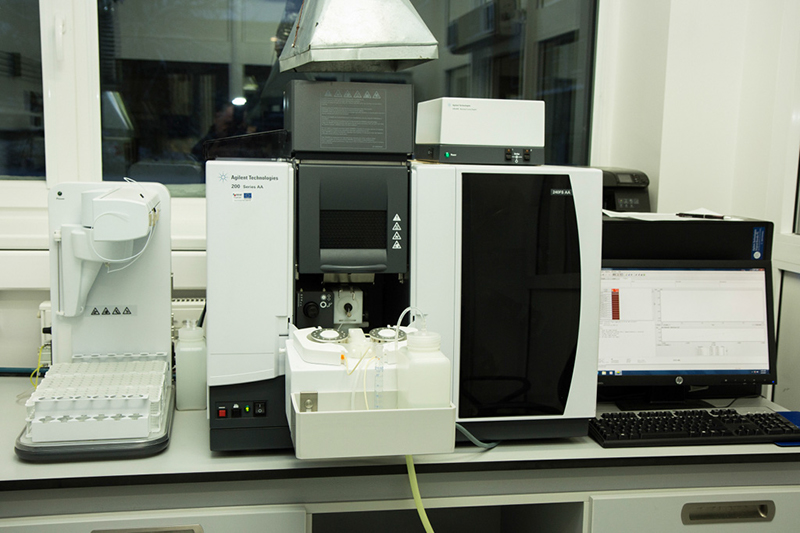

ESCA includes a sampling depth of about 30 Angstroms and can Provide the chemical composition and density of the passivation layer. This technique is also mentioned by the semiconductor industry in specifications for analysing the passivation of atomic absorption spectroscopy. The method uses an X-ray beam to excite a solid sample, Resulting from the emission of photoelectrons. A cross section evaluation of those photo electrons offers both compound and elemental bonding about a sample surface. The principal advantage of ESCA is its ability to examine a broad assortment of substances – such as fibers, metals, glasses, polymers, semi-conductors and paper- and discover surface components and their chemical state. The features utilized to evaluate passivated stainless steel are chromium -oxide to iron oxide rations and chromium-to-iron ratios. Both these ratios, as well as the density of the passivation layer can be measured utilizing ESCA.

Nitinol is a shape memory alloy with superplastic properties. Nonetheless, to be utilised in medical devices, the metal should be passivated to prevent corrosion and any potential leaching of nickel inside the human body. ESCA is a beneficial way of assessing the passivated Nitinol surface to the presence or lack of invisibly to the human body. ESCA is a beneficial way of assessing the passivated Nitinol surface to the existence or non-presence of nickel and determining the density of the passivation layer. Nitinol will normally passivate by forming a titanium oxide coating on the surface. Hardness Measurement: The robustness of a metal is often Regarded as the most vital property because it is utilized in design and quality and can be quantified relatively easily. The hardness may give a sign of success and strength of a heat treatment process. Standard hardness measurement methods include Rockwell, Brinell, microhardness and document.