Rapid Tooling can be described as a showing strategy which improves and quickens the headway of new things. It is a strategy that uses PC upheld mechanical assemblies and methodologies, for instance, 3D printing and sound framework lithography to make physical thing models for creation tooling and examination. The technique can be especially helpful to thing organizers, part suppliers and even makers and goes with different good conditions to all who choose to use the system.

It saves time

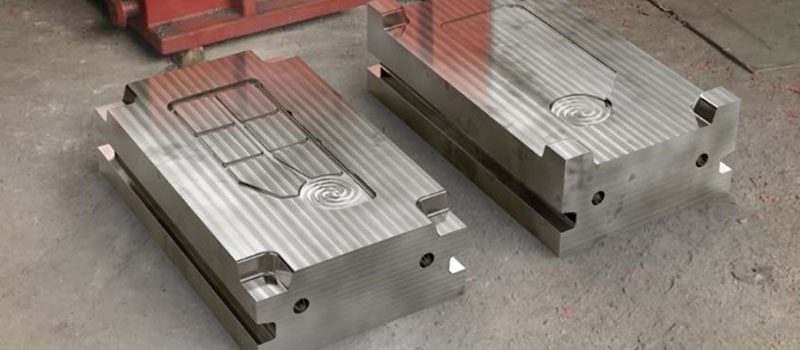

Rapid Tooling discards continually that is needed to make plans, novel devices and Molds for normal illustrating. There is a huge time decline between the fundamental organizing and the assessment and these movements up the creation system. The exact model is made rapidly open for incorporate, convenience, execution and structure testing using the method something that would have put aside a long exertion to achieve using the standard procedure. This is because the strategy is generally automated and originators can even change things snappier and before huge scope producing. You would now have the option to get your things in the market brisk and before your adversaries.

It opens up advancement openings

Another huge favored situation of the prototyping is that fashioners have the occasion to make models that are flighty in surfaces and shaped without worrying about exact creation. This is something that would have been unlimited or dull to achieve with standard prototyping because of impediments in physical sections and model tooling. Ingenuity is taken to the accompanying level by Rapid Tooling strategy.

It reduces costs

This system diminished thing improvement costs in light of the fact that no special instruments are needed for each new thing. It is a method that relies upon printing rigging and CAD all the time thusly diminishing expenses. There rapid tooling is also decreased work contemplating that the methodology is robotized and an association does not in this manner require having a huge staff gathering to finish the work. The waste costs are similarly restricted by the methodology considering the way that there is no material chipping that ends up getting a finished model using the conventional techniques.

It offers more straightforward portrayal

3D Molds are handy and easy to present to clients or accomplices because of straightforward survey in light of everything and edges that issue. With this discernment, the improvement program is asserted rapidly since it is more straightforward for everyone needed to fathom the thing undoubtedly. It is much less difficult to separate the thing when it is possible to reach it and view all parts appeared differently in relation to relying upon a printed transformation of a comparative thing advantages of rapid tooling. Huge changes should similarly be conceivable to improve the thing.